fineline technologies

December 17, 2025

fineline technologies proposal! fineline technologies official support.GOV,fineline technologies active!

<h1>Fineline Technologies: Precision Engineering for Modern Applications</h1>

<p>Fineline technologies represent the pinnacle of precision manufacturing and micro-engineering. In my professional journey within the electronics sector, I've consistently observed that the demand for finer tolerances and miniaturized components isn't just a trend—it's the fundamental trajectory of technological progress. My personal aptitude has always leaned towards detailed, meticulous work, which is why I find the world of fineline technologies so compelling. It's a field where a skill for precision translates directly into innovation.</p>

<h2>The Core of Fineline Innovation: Advanced PCB Manufacturing</h2>

<p>My view is that the most significant impact of fineline technologies is seen in Printed Circuit Board (PCB) fabrication. The ability to create traces and spaces measured in microns unlocks possibilities for more powerful, compact, and efficient devices. For a fun application, consider modern high-performance gaming mice. Their responsive accuracy is largely due to fineline PCBs that pack sophisticated sensor chips onto incredibly small boards, allowing for lightning-fast signal processing and minimal lag.</p>

<h3>Technical Specifications: A Fineline PCB Stackup</h3>

<p>For those developing next-generation hardware, here are detailed technical parameters for a typical 8-layer fineline PCB stackup. *These technical parameters are for reference only; specifics must be confirmed by contacting backend management.*</p>

<h4>Layer 1 (Top Signal):</h4>

<ul>

<li>Material: FR-4, Tg 170°C</li>

<li>Finished Copper Weight: 1/2 oz (17.5 µm)</li>

<h2>The Core of Fineline Innovation: Advanced PCB Manufacturing</h2>

<p>My view is that the most significant impact of fineline technologies is seen in Printed Circuit Board (PCB) fabrication. The ability to create traces and spaces measured in microns unlocks possibilities for more powerful, compact, and efficient devices. For a fun application, consider modern high-performance gaming mice. Their responsive accuracy is largely due to fineline PCBs that pack sophisticated sensor chips onto incredibly small boards, allowing for lightning-fast signal processing and minimal lag.</p>

<h3>Technical Specifications: A Fineline PCB Stackup</h3>

<p>For those developing next-generation hardware, here are detailed technical parameters for a typical 8-layer fineline PCB stackup. *These technical parameters are for reference only; specifics must be confirmed by contacting backend management.*</p>

<h4>Layer 1 (Top Signal):</h4>

<ul>

<li>Material: FR-4, Tg 170°C</li>

<li>Finished Copper Weight: 1/2 oz (17.5 µm)</li>

<li>Minimum Trace/Space: 2.5 mil / 2.5 mil (63.5 µm)</li>

</ul>

<li>Minimum Trace/Space: 2.5 mil / 2.5 mil (63.5 µm)</li>

</ul>

<h4>Inner Layers (L2-L7):</h4>

<ul>

<li>Material: FR-4 Core & Prepreg</li>

<li>Dielectric Thickness (between layers): 3.5 mil (89 µm) typical</li>

<li>Laser Drilled Microvia Diameter: 4 mil (102 µm) finished</li>

<li>Primary Chipset Landing Pattern: For a BGA with 0.4mm pitch, using 0.2mm (8 mil) solder mask defined pads.</li>

</ul>

<h4>Layer 8 (Bottom Signal):</h4>

<h4>Inner Layers (L2-L7):</h4>

<ul>

<li>Material: FR-4 Core & Prepreg</li>

<li>Dielectric Thickness (between layers): 3.5 mil (89 µm) typical</li>

<li>Laser Drilled Microvia Diameter: 4 mil (102 µm) finished</li>

<li>Primary Chipset Landing Pattern: For a BGA with 0.4mm pitch, using 0.2mm (8 mil) solder mask defined pads.</li>

</ul>

<h4>Layer 8 (Bottom Signal):</h4>

<ul>

<ul>

<li>Specifications mirror Layer 1.</li>

<li>Overall Board Thickness: 1.0mm ±10%</li>

<li>Surface Finish: Electroless Nickel Immersion Gold (ENIG), 3-5 µm Ni, 0.05-0.1

<li>Specifications mirror Layer 1.</li>

<li>Overall Board Thickness: 1.0mm ±10%</li>

<li>Surface Finish: Electroless Nickel Immersion Gold (ENIG), 3-5 µm Ni, 0.05-0.1

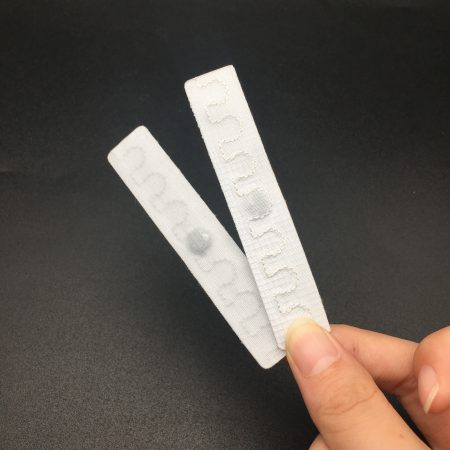

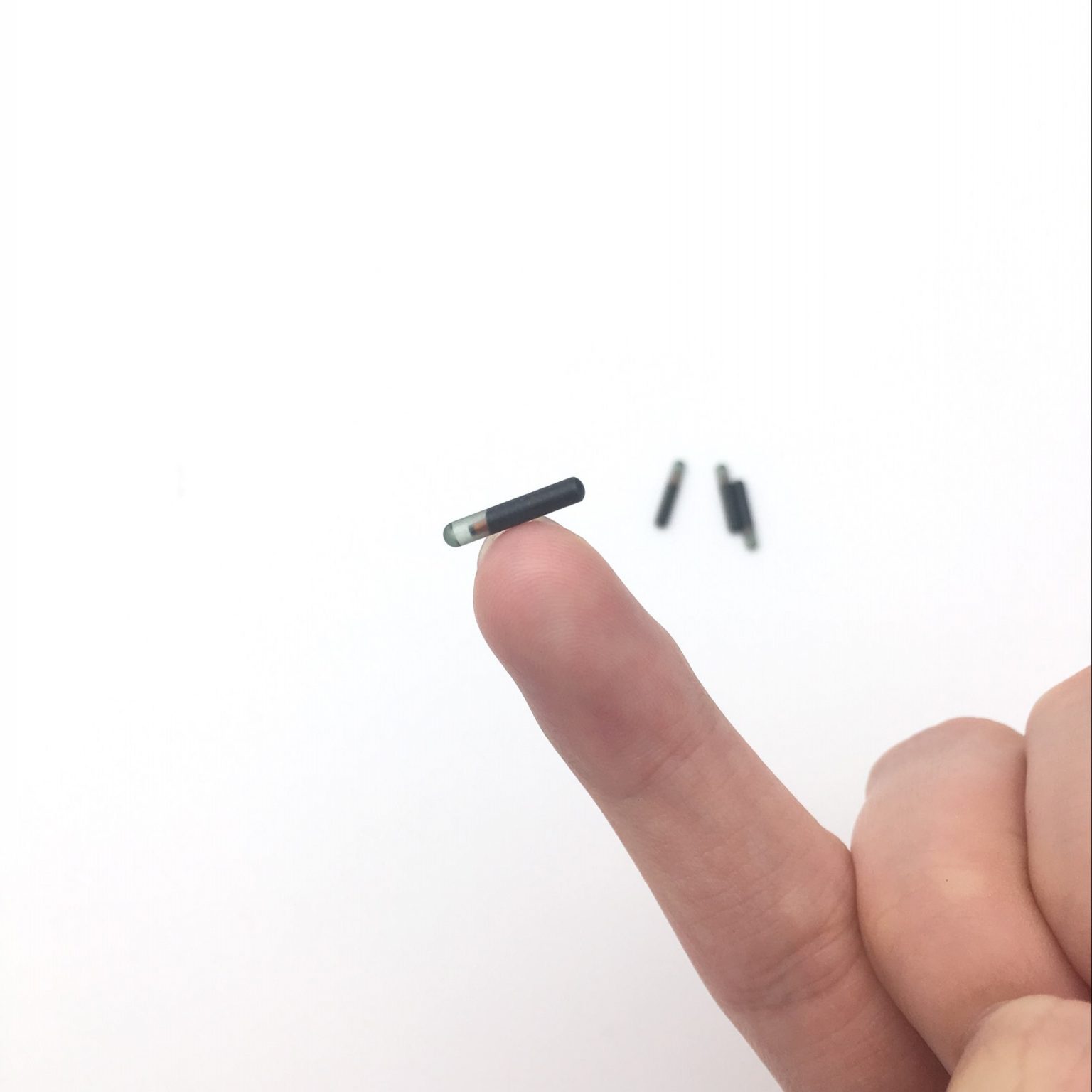

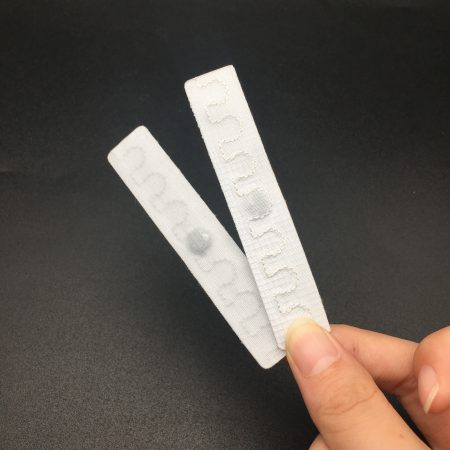

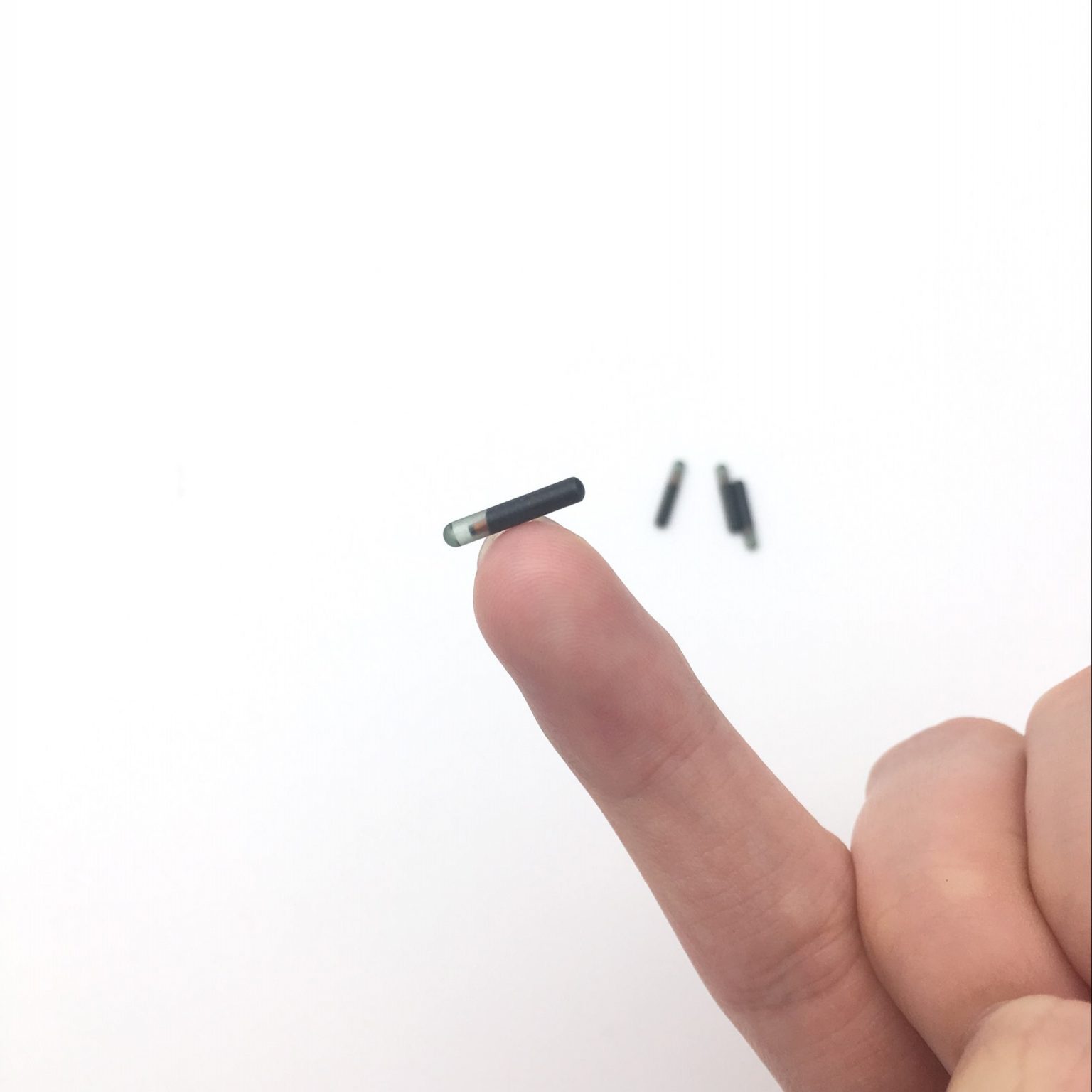

The Use of RFID for Human Identity Verification

<h2>The Core of Fineline Innovation: Advanced PCB Manufacturing</h2>

<p>My view is that the most significant impact of fineline technologies is seen in Printed Circuit Board (PCB) fabrication. The ability to create traces and spaces measured in microns unlocks possibilities for more powerful, compact, and efficient devices. For a fun application, consider modern high-performance gaming mice. Their responsive accuracy is largely due to fineline PCBs that pack sophisticated sensor chips onto incredibly small boards, allowing for lightning-fast signal processing and minimal lag.</p>

<h3>Technical Specifications: A Fineline PCB Stackup</h3>

<p>For those developing next-generation hardware, here are detailed technical parameters for a typical 8-layer fineline PCB stackup. *These technical parameters are for reference only; specifics must be confirmed by contacting backend management.*</p>

<h4>Layer 1 (Top Signal):</h4>

<ul>

<li>Material: FR-4, Tg 170°C</li>

<li>Finished Copper Weight: 1/2 oz (17.5 µm)</li>

<h2>The Core of Fineline Innovation: Advanced PCB Manufacturing</h2>

<p>My view is that the most significant impact of fineline technologies is seen in Printed Circuit Board (PCB) fabrication. The ability to create traces and spaces measured in microns unlocks possibilities for more powerful, compact, and efficient devices. For a fun application, consider modern high-performance gaming mice. Their responsive accuracy is largely due to fineline PCBs that pack sophisticated sensor chips onto incredibly small boards, allowing for lightning-fast signal processing and minimal lag.</p>

<h3>Technical Specifications: A Fineline PCB Stackup</h3>

<p>For those developing next-generation hardware, here are detailed technical parameters for a typical 8-layer fineline PCB stackup. *These technical parameters are for reference only; specifics must be confirmed by contacting backend management.*</p>

<h4>Layer 1 (Top Signal):</h4>

<ul>

<li>Material: FR-4, Tg 170°C</li>

<li>Finished Copper Weight: 1/2 oz (17.5 µm)</li>

<li>Minimum Trace/Space: 2.5 mil / 2.5 mil (63.5 µm)</li>

</ul>

<li>Minimum Trace/Space: 2.5 mil / 2.5 mil (63.5 µm)</li>

</ul>

<h4>Inner Layers (L2-L7):</h4>

<ul>

<li>Material: FR-4 Core & Prepreg</li>

<li>Dielectric Thickness (between layers): 3.5 mil (89 µm) typical</li>

<li>Laser Drilled Microvia Diameter: 4 mil (102 µm) finished</li>

<li>Primary Chipset Landing Pattern: For a BGA with 0.4mm pitch, using 0.2mm (8 mil) solder mask defined pads.</li>

</ul>

<h4>Layer 8 (Bottom Signal):</h4>

<h4>Inner Layers (L2-L7):</h4>

<ul>

<li>Material: FR-4 Core & Prepreg</li>

<li>Dielectric Thickness (between layers): 3.5 mil (89 µm) typical</li>

<li>Laser Drilled Microvia Diameter: 4 mil (102 µm) finished</li>

<li>Primary Chipset Landing Pattern: For a BGA with 0.4mm pitch, using 0.2mm (8 mil) solder mask defined pads.</li>

</ul>

<h4>Layer 8 (Bottom Signal):</h4>

<ul>

<ul>

<li>Specifications mirror Layer 1.</li>

<li>Overall Board Thickness: 1.0mm ±10%</li>

<li>Surface Finish: Electroless Nickel Immersion Gold (ENIG), 3-5 µm Ni, 0.05-0.1

<li>Specifications mirror Layer 1.</li>

<li>Overall Board Thickness: 1.0mm ±10%</li>

<li>Surface Finish: Electroless Nickel Immersion Gold (ENIG), 3-5 µm Ni, 0.05-0.1Phone: +86 19925232774

Hours: Mon-Fri 9:00AM - 6:30PM